Programme functions

win-klima is the "productive" programme part of win-klimaX. With win-klimaX the components previously recorded in win-klimaX are processed further for the subsequent production. Furthermore you plan with win-klima the material and work resources and always have an overview of your current orders.

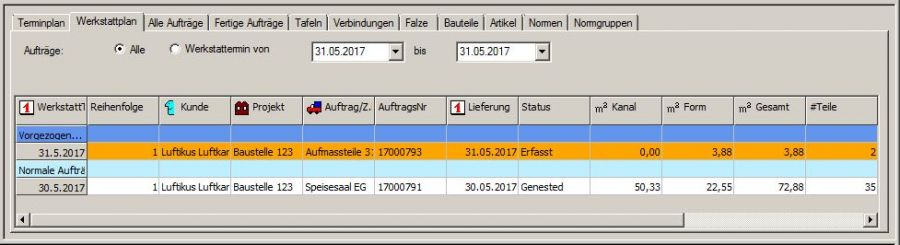

Resource & schedule planning

win-klima helps you to make optimum use of your production resources. Workshop plans are generated on the basis of the key production figures you set, the output in m2 per working day depending on the size of the components and the specified delivery dates. Furthermore, you will also be able to identify possible free resources of your production and to better estimate the possible production output.

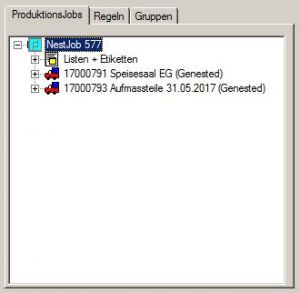

NestJob's

For the production the orders previously created in win-klimaX are transferred to NestJobs. In a nest job different orders can be merged and nested together, project and customer overlapping. In many cases this leads to a better use of the material, as the free spaces are filled with small parts in the case of orders with unfavourable edge lengths.

Nesting together

Up to 10 different jobs can be nested together in one nest job.

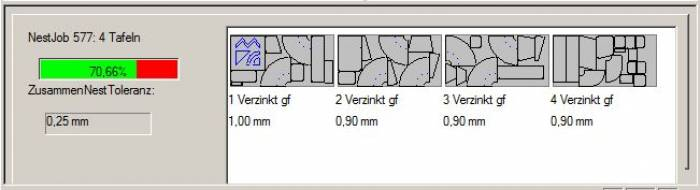

Better material utilisation

The material utilization can be improved even after nesting by adding other orders, especially if they contain small components. This is particularly important when using fixed sheet formats.

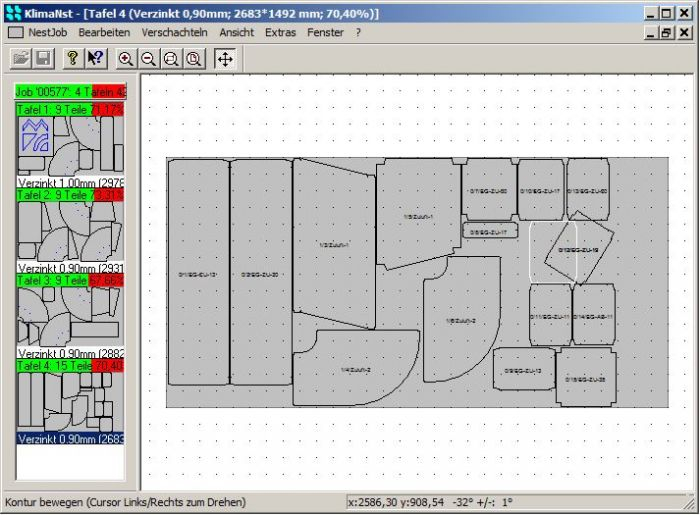

Cross sections and post-processing

After nesting, the cutting patterns can still be edited manually with the KlimaNest programme. Here the individual component contours can be rotated and moved across the board. Of course KlimaNest differentiates between the different materials and material thicknesses and informs you, if you try to move a contour across the material. You can also add more empty sheets to process the cutting residues of past orders if necessary.

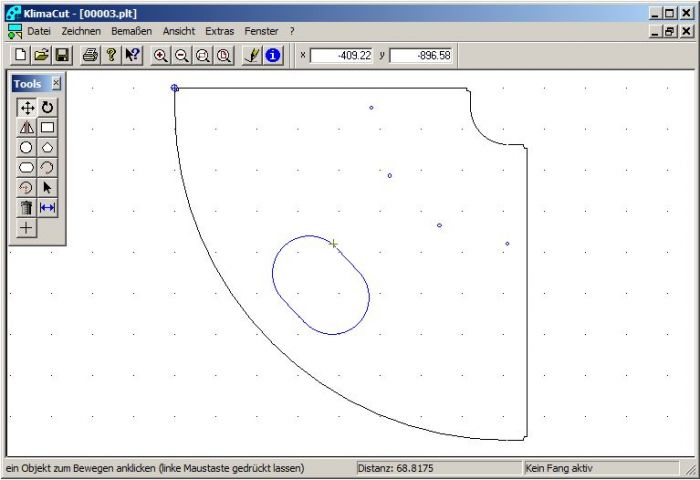

Contour machining with KlimaCut

With the KlimaCut program you can manually process every contour of every component. In this way, for example, special solutions for revision openings can be added to every component and this in every position. Thus all imaginable cut-outs are possible, even if they cannot be automatically displayed in win-klimaX.

Machine connection

For win-climate, we offer a wide range of postprocessors for machine connection. Devices of the following manufacturers of plasma and channel machines, lasers, punches and saws can be controlled with win-klima:

- Amada

- Biesse

- Cybermation

- Elpromatic

- ESAB

- ESPRIT Automation Ltd.

- Farley

- FinnPower

- Forstner

- Harmuth CNC

- Koike

- Lockformer

- Lovent

- LSS GmbH

- L-Tec

- MB-Portatec GmbH

- Messer Griesheim

- MicroStep

- SAF

- Salvagnini

- Spiro

- Tormec

- Trumpf

- Twin Seam

- Zinser

* Further manufacturers on request.

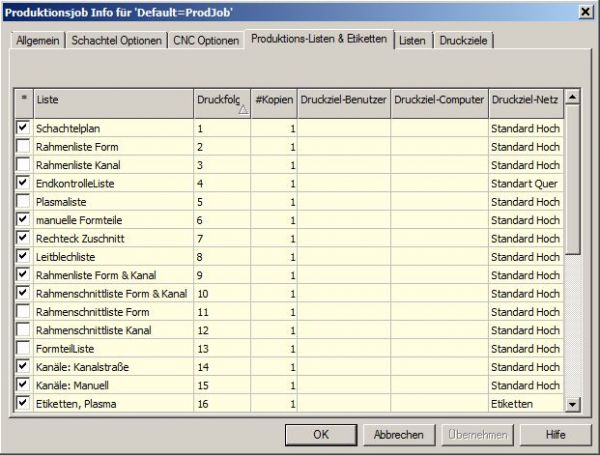

Production lists

win-klima provides you with lists and labels for all production processes. The list below shows only a part of the total available lists and labels.

For the overview of the entire NestJob or the individual orders:

For cutting on the plasma machine:

For the allocation of the finished components:

For components to be produced manually:

For the production of the straight ducts on the duct road:

For the production of the connections:

The printing of these lists can be fully automated. For this purpose, the print destination, number of copies and print sequence are set for each list and label type. The print destinations can be local or network printers.

Final inspection

The final inspection can be carried out with the help of our final inspection system e-traX. e-traX enables you to scan the individual components quickly and easily to find out whether all components of the order have been recorded.

Further information on e-traX can be found here!